Description

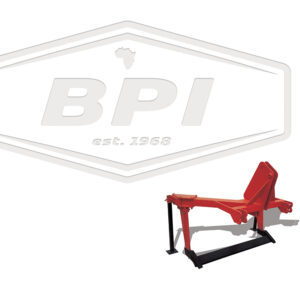

- This primary soil tillage machine is mounted on the tractor?s hydraulic lifting unit and universal three-point linkage system, making transport easy

- The mounting tower has been welded at 90? on a ?V? Frame constructed out of 100mm x 150mm x 10mm rectangular tubing. The tine assemblies are bolted on for easy row spacing

- Mainly used for breaking and aerating wheel tracks and hard core underground banks (plough banks). and these rippers / sub soilers break the ?plough bank? and can work from 400mm to 750mm, allowing moisture, nutrients and the roots of the plant to penetrate deeper

- Rippers / Sub Soilers come in various models and sizes from 1 tine to 5 tines, straight and curved tines and different working depths from 400mm to 750mm. The design of the tine allows for minimum soil disruption / disturbance thus preserving moisture in the soil

- Tines are protected by a shear bolt protection system and the shear bolt is easily replaced when the tine encounters obstructions underground

Reviews

There are no reviews yet.